Combat Robotics - “Washing Machine”

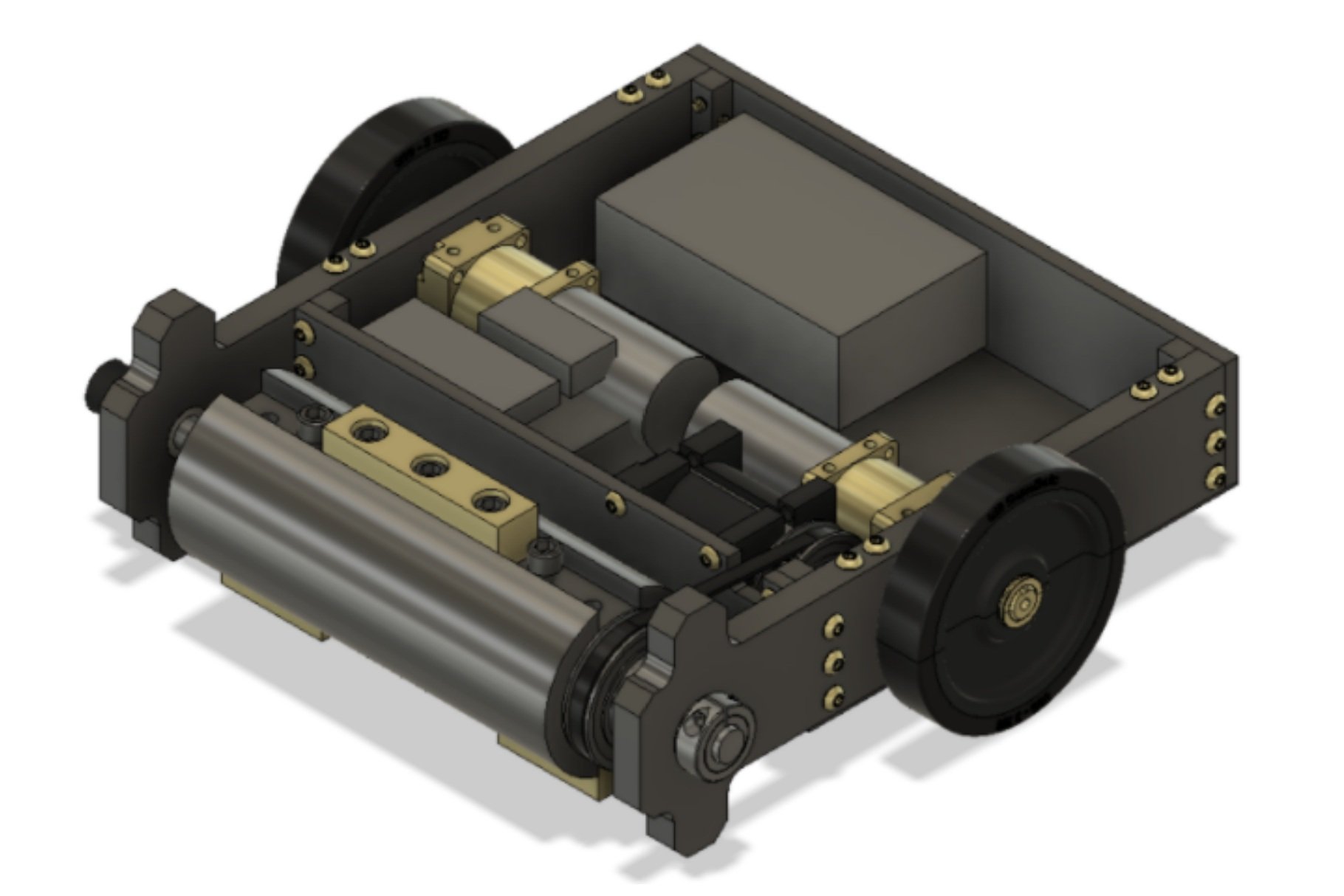

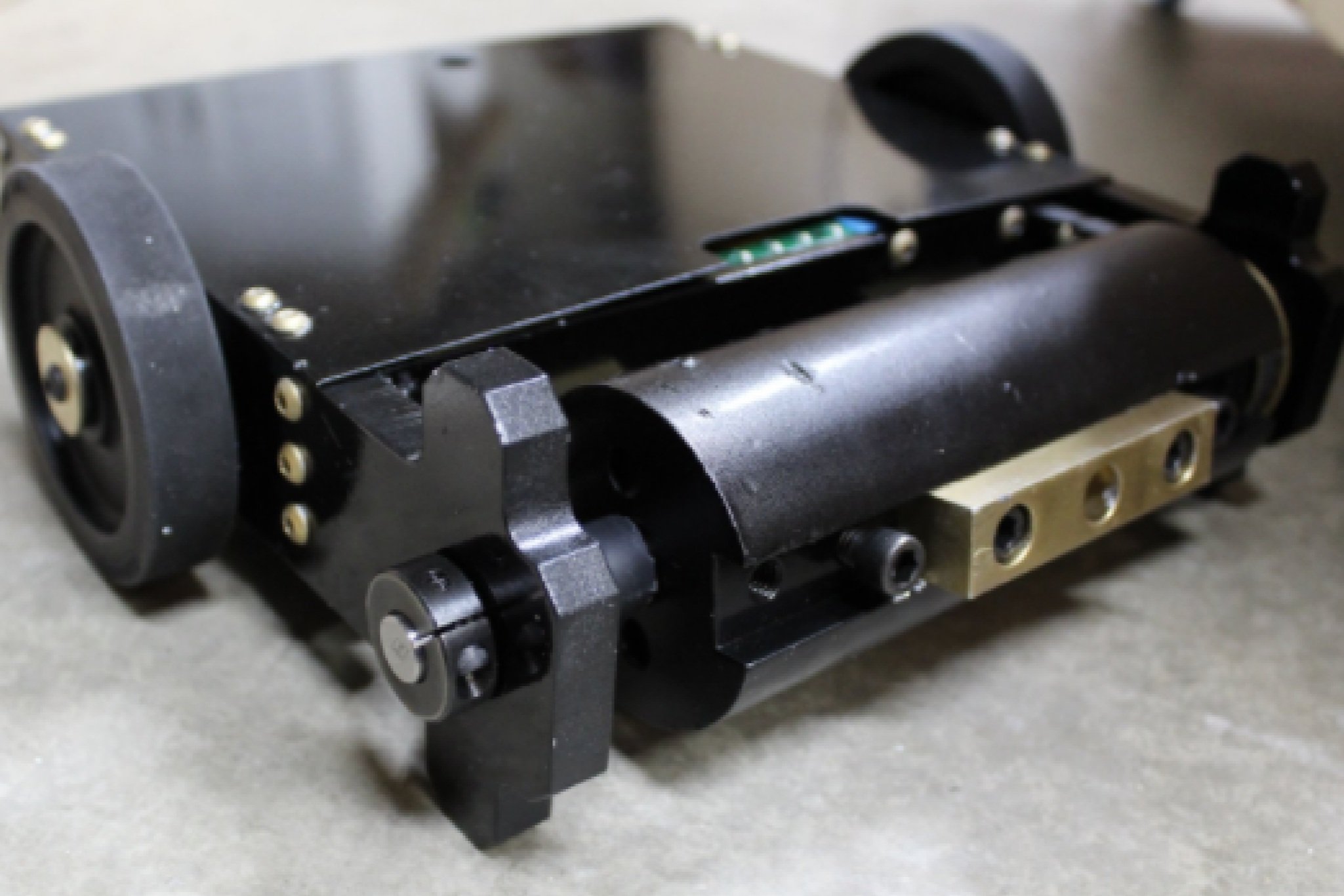

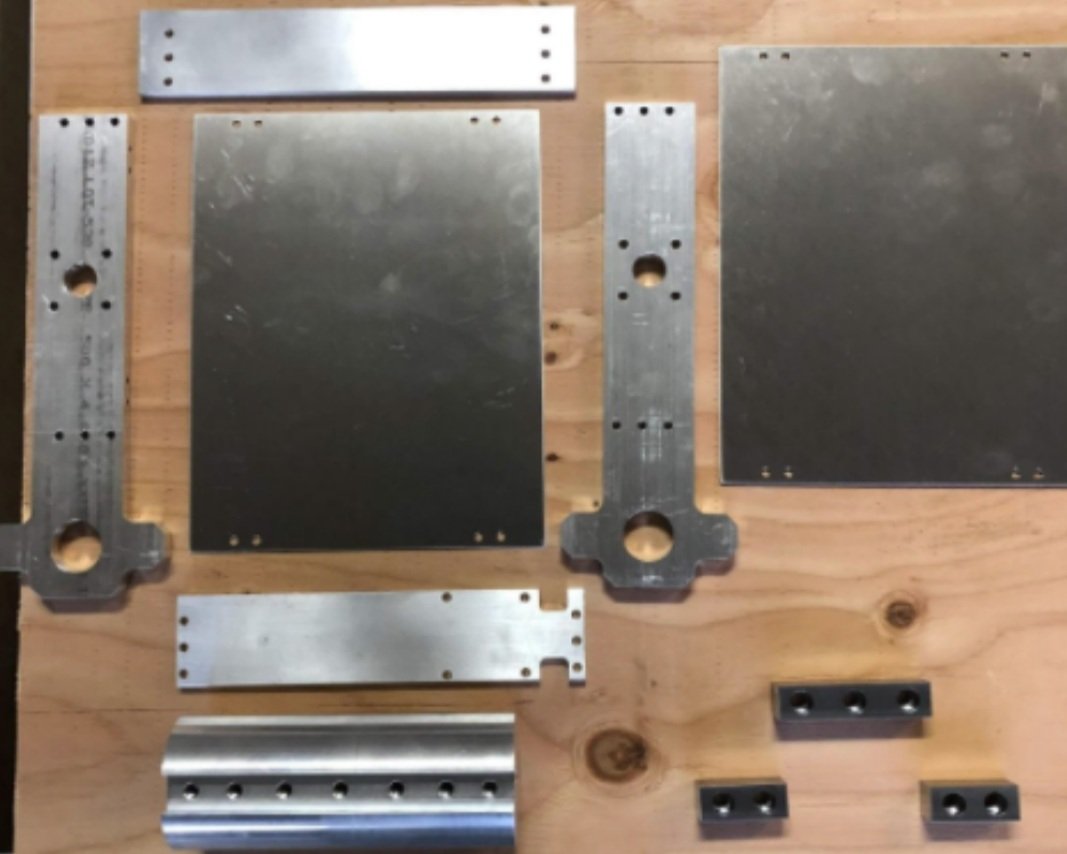

As the team captain and mechanical designer of my first combat robot, I CADed and directed the 3 and 5 person electronics and assembly teams to create the 15lb drum spinner “Washing Machine.” Washing Machine balances an offense-focused strategy with durability and ease of repair between matches. Working with our machining partner, I optimized the design to minimize manufacturing operations for the 6061-T6 aluminum chassis and drum on a CNC mill and lathe. The rotationally balanced weapon design leveraged inset, offset teeth and achieved a maximum tip speed of 241.7 mph and the kinetic energy of a gram of TNT. As a high school rookie team, Washing Machine defeated experienced BattleBot builders to win the NRL Southern California Championship, proceeded to finish 9th at the NRL Nationals against the top high schools and college teams in the country, and since then has received an award at every competition it has been to.

First complete iteration of the Fusion 360 mechanical assembly

The weapon assembly with staggered teeth to allow for the same engagement at higher speeds. Teeth made from S7 tool steel, hardened to 54 HRC for peak impact toughness.

Washing machine repaired for its 2nd 15 lb competition

CNC mill and lathe machined components made out of 6061-T6 Aluminum due to its strength per weight and preferred failure mode of plastic deformation over cracking