Glitch on BattleBots

Weapon Design

I designed Glitch’s 58 lb weapon focusing on maximizing energy transfer (in KE and deformation), winning the highest percentage of engagements, and being durable enough to give and take hits.

Weapon profile meant to taper away to avoid opponent hits, counterbalance depth, and ideal weapon speed calculated from an estimated 25 mph engagement speed (depends on specific opponent drive speed)

S7 tool steel hardened to 54 HRC for peak energy absorption and dig into the typical 47 HRC AR500 armor

Offset design and hollow shape meant to maximize stored energy via weapon rpm and MoI/mass given a fixed feed rate

Sized weapon motors as a tradeoff between the calculated spin up time and weight in the motors, ESCs, and LiPo batteries

Explosive weapon hit in the Rotator “BattleBots: Champions” finals

Event simulation of a weapon strike. Simulations of varying attacking and defending hits were repeated to optimize shape and remove stress risers

Designed from 2 planes and heat treated before machining in order to wire EDM machine. Process chosen to avoid work hardening and heat treating deformations

Damage into 1/4” AR500 armor from Glitch’s weapon, which can impart up to 40 kJ and has cracked internals from shock

Drive Design

A key factor when applying for BattleBots is a robot’s uniqueness. Glitch’s selling point is its strafing X-Drive and the stealth bomber looking frame shape that came along with it. Teams struggle to drive on the torn up, unreplicatable BattleBots floor, and using offset omni wheels created an extra challenge.

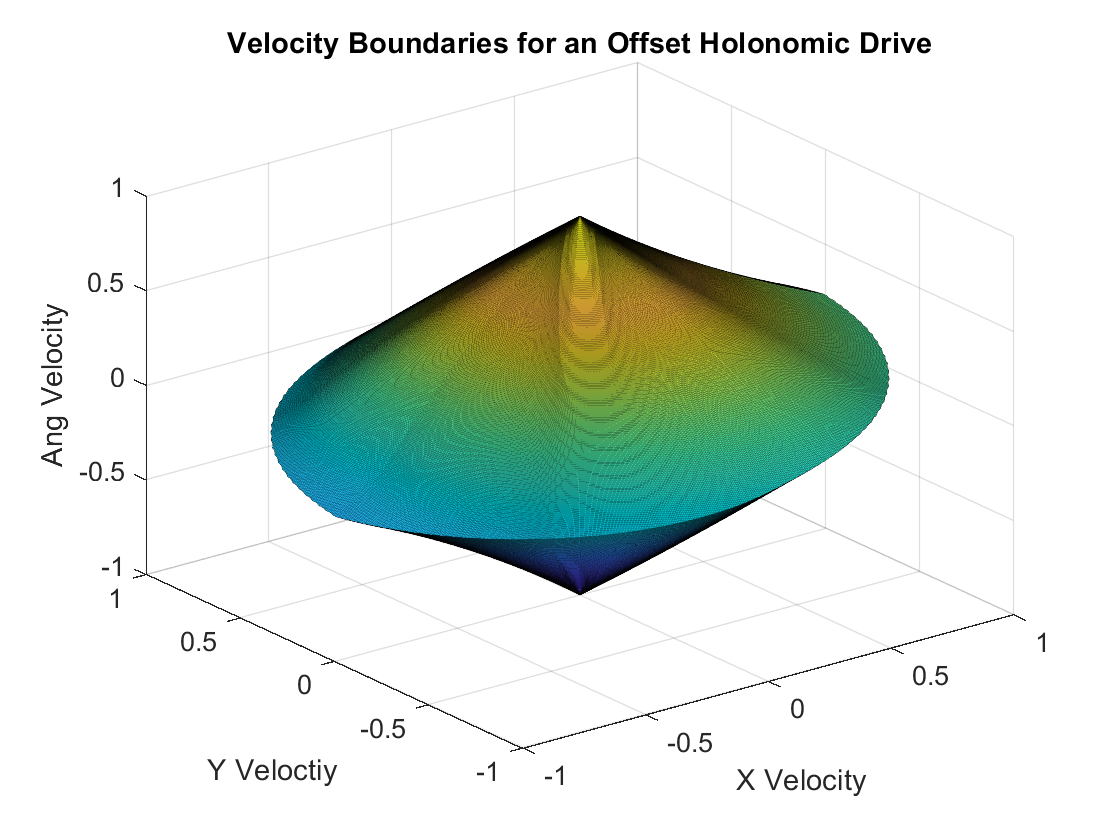

4 omni wheels vector add to create holonomic movement. Since the front and back wheels have an imbalanced moment around the CoM, I derived a method to delink strafing from turning applicable for precise movement of all non-standard shaped omni wheel drives

Sized drive motor for an 18 mph top speed and 90% acceleration distance of 5 feet given traction limits

Our biggest difficulty with Glitch V1 was traction, despite compensating for the geometric sqrt(2) less traction with magnet downforce. The omni wheels had hard rubber, less rubber thickness, and with a rigid frame wheels would have equal enough traction to vector correctly. For Glitch V2 I provided design reviews, design decisions, and aided in some manufacturing of the suspension system, custom wheels and cast rollers

The first Glitch V2 drive test for BattleBots World Championship 7

Vx, Vy & ω inputs are processed via a psuedoinverse and several normalizations to calculate wheel outputs

Values are converted from joystick inputs and mixed via Lua onboard the transmitter

Frame Design

Designing Glitch’s frames was an extremely iterative process since my goal was to optimize as much as possible the strength to weight ratio and interactions between Glitch’s subsystems. The frame impacts almost everything about the design, like fine tuning the position of the wheels and armor relative to the weapon, mounting systems, and orienting the outer armor shell in both an effective and aesthetic manner.

To reduce stress risers at the 45 degrees joints required by omni wheels, Glitch’s primary structure is a 4 ft wide aluminum billet, with taller weapon mounting rails to minimize manufacturing cost

6061 Aluminum chosen for cost, strength to weight, and preferred combat-typical structural failure mode of deformation over cracking

Improved repairability for after fight damage in V2 design, including solving a problem where outside facing armor screws would jam by replacing them with rubber mounted TI dowel pins, making sure every component can be removed straight vertically, and increasing tolerances by using rubber for weapon motor and drive pod mounting as well

Designed to quickly swap subsystems to a repaired frame to meet fight deadlines

The frame CAD has over 1000 saved versions from our BattleBots application to Season 6 & 7

Negotiated with overseas manufacturing partners to decrease 5 axis CNC lead time without changing prices

One of 5 electronics pods for Glitch V2, for easier quick swap repairs

Glitch V2’s frame fresh from our manufacturer!

Team Management & Miscellaneous

Grew the Combat Robotics at Berkeley club from 0 to 55 members in 2 years, guiding and acting as the lead design reviewer for 10 teams as they developed combat specific and general engineering skills

Led two iterations of the 20 person design, manufacturing and competing of Glitch in ~1 year build cycles and an intense 2 week of fights and repairs

Developed business relationships with sponsors to fund the organization’s growth and with machine shop partners to help manufacture complex parts

Developed the “Glitch'“ brand, in robot form factor to outfit planning, driving 7% of our budget in merge sales

Render I made in Blender for our initial BattleBots application